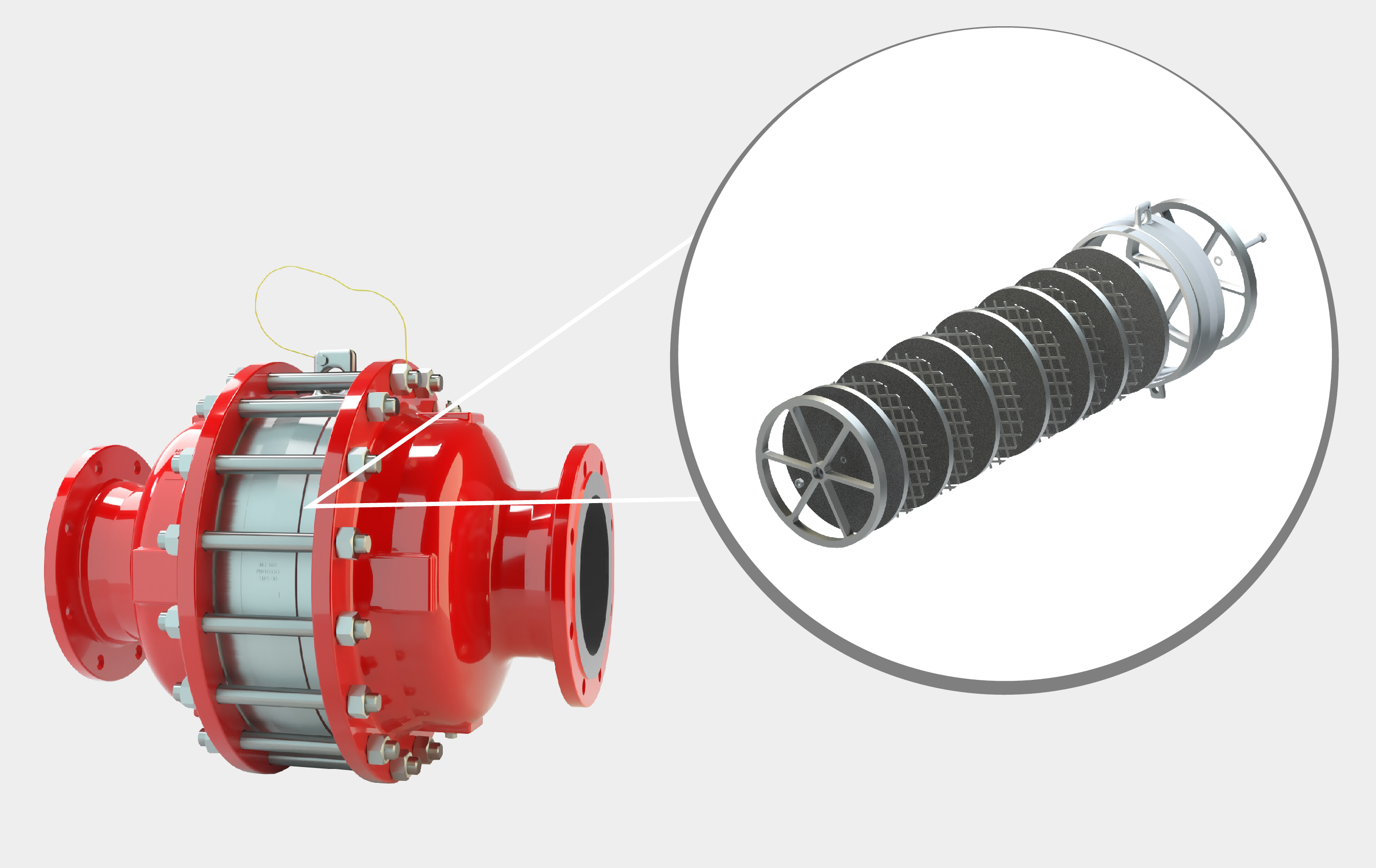

Engineered for superior safety and compliance, PROTEGO® Flame Arresters offer unmatched protection against deflagrations and detonations.

Mitigate Explosion Risks with PROTEGO® Flame Arresters

Our Key Benefits

- Industry-Leading Expertise

- Proven Performance and Reliability

- Emission Reduction Compliant

- Mitigate Explosion Risks with PROTEGO® Flame Arresters

Why Choose PROTEGO® Flame Arresters?

In hazardous industrial environments, safety is paramount. PROTEGO® Flame Arresters are essential components in preventing catastrophic explosions.

- Industry-Leading Expertise: PROTEGO®'s foundation in Flame Arrester technology spans decades, ensuring unmatched knowledge and reliability.

- Proven Performance: Our Flame Arresters are leading by global standards, trusted by industries worldwide.

- Engineered Excellence: Designed by engineers for engineers, ensuring optimal performance in complex industrial environments.

- Integral to safety systems: PROTEGO® Flame Arresters are essential components for vapour combustion systems and flares.

- Emission Reduction Compliant: Our Flame Arresters are crucial to emission reduction strategies, helping your company meet environmental regulations.

- Versatile Application: From oil and gas to chemical processing, our Flame Arresters adapt to diverse industrial needs.

- Part of Comprehensive Safety Solutions: Integrate our Flame Arresters with our venting technologies for complete protection.

- Customizable for Your Needs: Our technical experts tailor Flame Arrester solutions to your specific requirements.

- Globally Certified: Meet international safety standards with our widely approved Flame Arrester technology.

Key Features

- Certified to international safety standards (conformity according to the currently valid ATEX directive, approvals according to other national/international regulations on request).

- Robust construction for long-lasting performance.

- Optimized flow capacity and minimal pressure drop.

- Suitable for a wide range of industries and applications.

- Easy installation and minimal maintenance.

- Detonation and Deflagration protection.

- Detailed technical data available.

Where It’s Used & What It Delivers

Applications:

- Oil and Gas Refineries

- Chemical Processing Plants

- Storage Tank Facilities

- Vapor Combution Systems

- Flare Systems

Technical Specifications:

- Downloadable datasheets and brochures.

- Customizable solutions to meet specific requirements.

Compliance and Certifications:

- Conformity according to the currently valid ATEX directive.

- Approvals according to other national/international regulations on request.